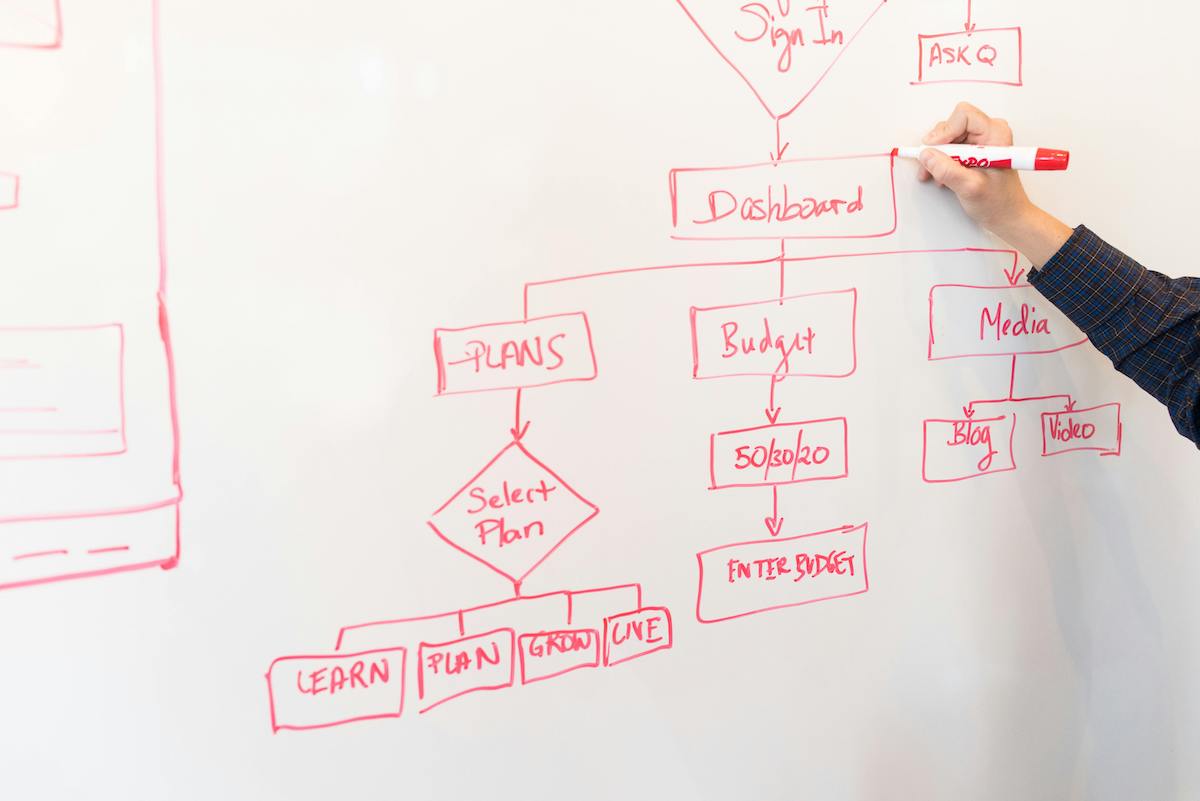

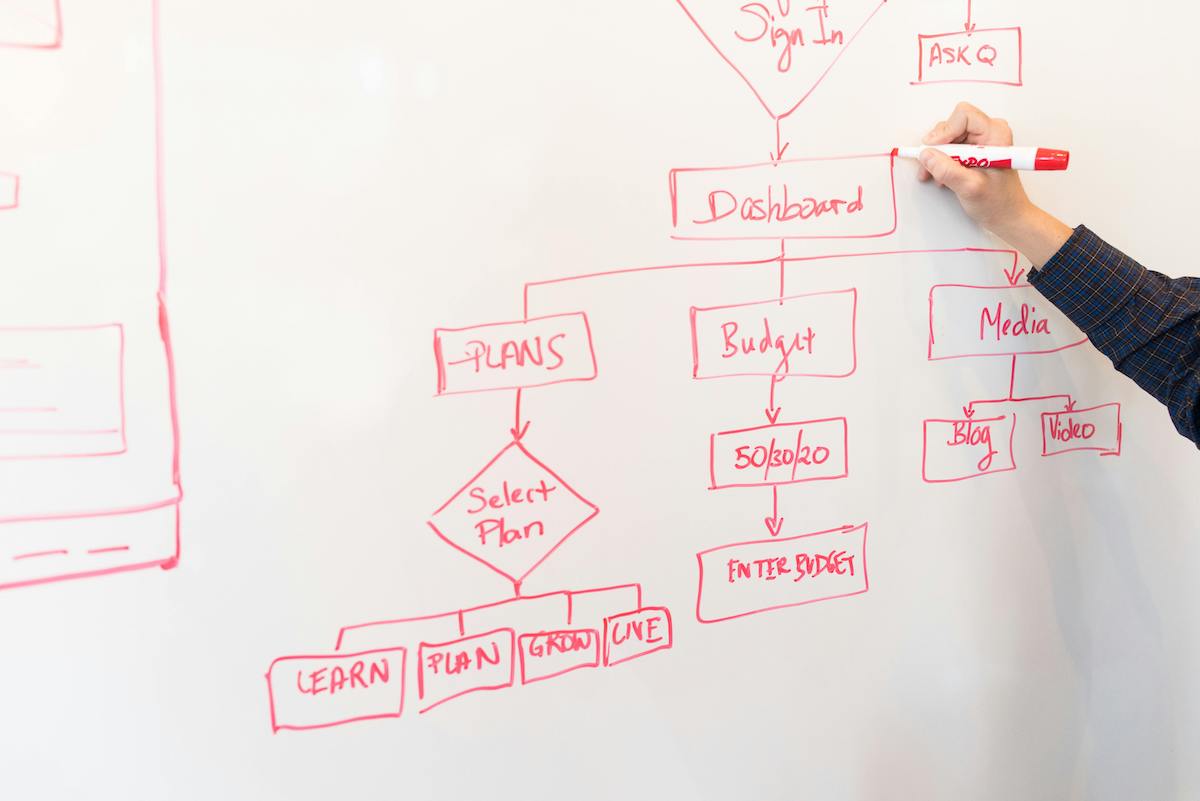

Process Analysis and Modeling

I map out the flow of materials in your system using a process flow diagram. This helps define system boundaries, identify inputs and outputs, and highlight key areas for improvement. I also simulate your processes under various conditions, offering ideas for process design, optimization, and testing through sensitivity and hypothesis analysis.

Mass Balance and Resource Efficiency Studies

I track and quantify material flow through your processes, ensuring all inputs are accounted for and identifying areas where resources—such as water, energy, and raw materials—are being wasted. This helps assess environmental impacts, minimize waste, improve resource efficiency, and reduce costs.

Techno-Economic Analysis and Scale-up Planning

I combine technical and economic evaluations to estimate both capital (CAPEX) and operational (OPEX) expenses. Mass balance analysis is crucial for businesses looking to scale. They provide data on resource requirements and waste outputs at larger production levels, helping with planning and investment decisions.